How Liquid Cooling Works

Liquid cooling has evolved from an enthusiast-only modification into a mainstream thermal solution for modern PCs. As CPUs and GPUs continue to push higher power limits, traditional air cooling often struggles to dissipate heat efficiently under sustained loads. Liquid cooling addresses this challenge by using fluid-based heat transfer to move thermal energy away from critical components more effectively.

Understanding how liquid cooling works requires examining the physics behind heat transfer, the components involved, and how modern liquid cooling systems are engineered for reliability and performance.

Why Liquid Cooling Exists

Air is a relatively poor conductor of heat. While advanced heatsinks and high-speed fans can manage moderate thermal loads, modern processors routinely exceed 200 watts under boost conditions. At these levels, air cooling approaches its practical limits.

Liquid cooling exists because liquids—particularly water-based coolants—can absorb and transport heat far more efficiently than air. This allows thermal energy to be moved quickly from the heat source to a larger surface area where it can be dissipated.

Studies in thermal engineering from IEEE and MIT consistently show that liquid-based cooling systems offer superior heat transfer efficiency in high-density electronic systems.

The Core Principle: Heat Transfer Through Liquid

Liquid cooling relies on three fundamental processes:

- Key Components of a Liquid Cooling System

Convection:

The coolant absorbs heat as it flows across the cold plate.

Dissipation:

The heated liquid moves to a radiator, where airflow removes heat and cools the liquid before it recirculates.

This continuous cycle allows liquid cooling systems to maintain lower component temperatures under sustained workloads.

Key Components of a Liquid Cooling System

Every liquid cooling system—whether an all-in-one unit or a custom loop—relies on the same core components.

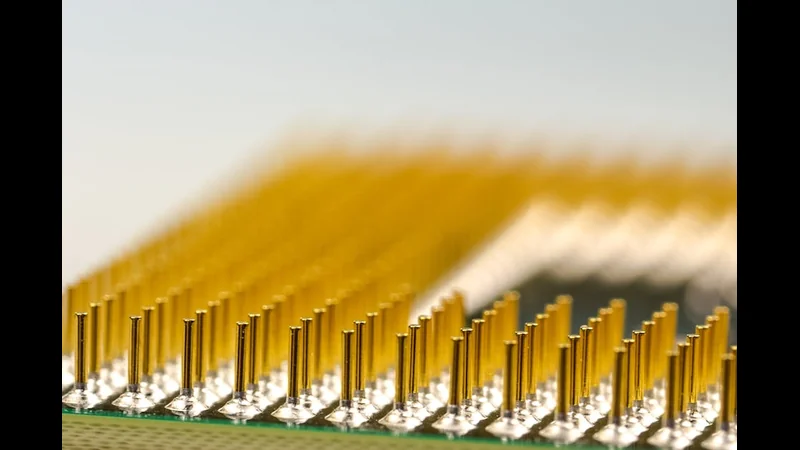

Cold Plate and Water Block

The cold plate sits directly on the CPU or GPU and serves as the primary interface for heat transfer. Microfins inside the block increase surface area, allowing the coolant to absorb heat more efficiently.

High-quality cold plates are precision-machined to ensure even contact and optimal thermal conductivity.

Pump: The Heart of the System

The pump circulates coolant through the loop. Its performance determines flow rate, which directly affects cooling efficiency.

Modern pumps are designed to:

- Operate quietly

- Maintain consistent flow

- Resist wear over long periods

- Adapt speed based on thermal demand

Pump reliability is critical—without flow, liquid cooling fails entirely.

Tubing and Coolant Flow

Tubing connects all components and allows coolant to move through the system. Tubing materials must resist permeation, temperature changes, and chemical breakdown.

- Coolants are typically water-based with additives that prevent corrosion

- biological growth

- mineral buildup.

Radiator: Where Heat Is Released

The radiator is where most heat dissipation occurs. It functions similarly to a car radiator, using airflow to remove heat from the liquid.

Radiator efficiency depends on:

- Surface area

- Fin density

- Fan quality

- Airflow direction

Larger radiators provide more thermal headroom, allowing quieter operation and better sustained performance.

Fans and Airflow Integration

Radiator fans are optimized for static pressure, enabling air to pass through dense fins. Fan curves are often controlled dynamically based on coolant or CPU temperature.

Proper airflow integration ensures that heat removed from the liquid does not recirculate inside the case.

AIO vs Custom Loop Liquid Cooling

Liquid cooling systems generally fall into two categories.

All-in-One (AIO) Coolers

AIO coolers are sealed units that integrate all components into a single package.

Advantages include:

- Easy installation

- Minimal maintenance

- High reliability

- Consistent performance

AIOs are the most common liquid cooling solution for CPUs and are increasingly available for GPUs.

Custom Loop Cooling

Custom loops are fully modular systems assembled from individual components.

Advantages include:

- Maximum cooling performance

- Support for cooling multiple components

- Custom aesthetics

- Superior thermal capacity

- However

- custom loops require careful planning

- regular maintenance

- higher upfront cost.

Liquid Cooling and Overclocking

Overclocking increases heat output significantly. Liquid cooling provides the thermal headroom needed to sustain higher clock speeds without throttling.

Benefits for overclocking include:

- Lower peak temperatures

- More stable boost behavior

- Reduced thermal throttling

- Improved component longevity

While liquid cooling does not guarantee higher overclocks, it removes thermal limitations as a primary constraint.

Reliability and Safety of Modern Liquid Cooling

Modern liquid cooling systems are far more reliable than early designs. AIO coolers are factory-sealed and tested for leaks, with extremely low failure rates.

Key safety features include:

- Reinforced tubing

- Secure fittings

- Pump failure detection

- Corrosion-resistant materials

While no system is entirely risk-free, liquid cooling is now considered safe for mainstream use when properly installed.

Liquid Cooling vs Air Cooling

Each cooling method has strengths and trade-offs.

Liquid cooling advantages:

- Superior heat transfer

- Better performance under sustained load

- Quieter operation at high power levels

- Air cooling advantages:

- Simpler design

- Lower cost

- Easier maintenance

- No liquid-related risks

- The choice depends on workload

- noise tolerance

- thermal requirements.

Cooling GPUs with Liquid Systems

GPUs generate more heat than CPUs in many systems. Liquid cooling is increasingly used to manage GPU thermals, especially in high-end gaming and workstation builds.

Liquid-cooled GPUs offer:

- Lower temperatures

- Higher sustained boost clocks

- Reduced fan noise

As GPU power consumption continues to rise, liquid cooling adoption is expected to grow.

The Future of Liquid Cooling

As hardware becomes more power-dense, liquid cooling will continue to evolve.

Emerging trends include:

- Direct-die cooling

- Microchannel cold plates

- Advanced coolants

- AI-controlled pump and fan behavior

- Hybrid air-liquid solutions

Liquid cooling is becoming an essential component of next-generation thermal management strategies.

FAQ

Is liquid cooling better than air cooling?

For high-performance systems, yes—especially under sustained load.

Do liquid coolers require maintenance?

AIOs require minimal maintenance; custom loops require regular upkeep.

Is liquid cooling risky?

Modern systems are very safe when installed correctly.

Does liquid cooling reduce noise?

Often yes, particularly at high power levels.

Can liquid cooling extend component lifespan?

Lower operating temperatures generally improve longevity.

Conclusion

Liquid cooling works by leveraging the superior thermal properties of liquids to move heat away from high-power components efficiently. Through a carefully engineered cycle of conduction, convection, and dissipation, liquid cooling systems enable modern CPUs and GPUs to operate at higher performance levels for longer periods.

As computing hardware continues to push thermal boundaries, liquid cooling is no longer a luxury—it is becoming a practical necessity for sustained performance and stability.